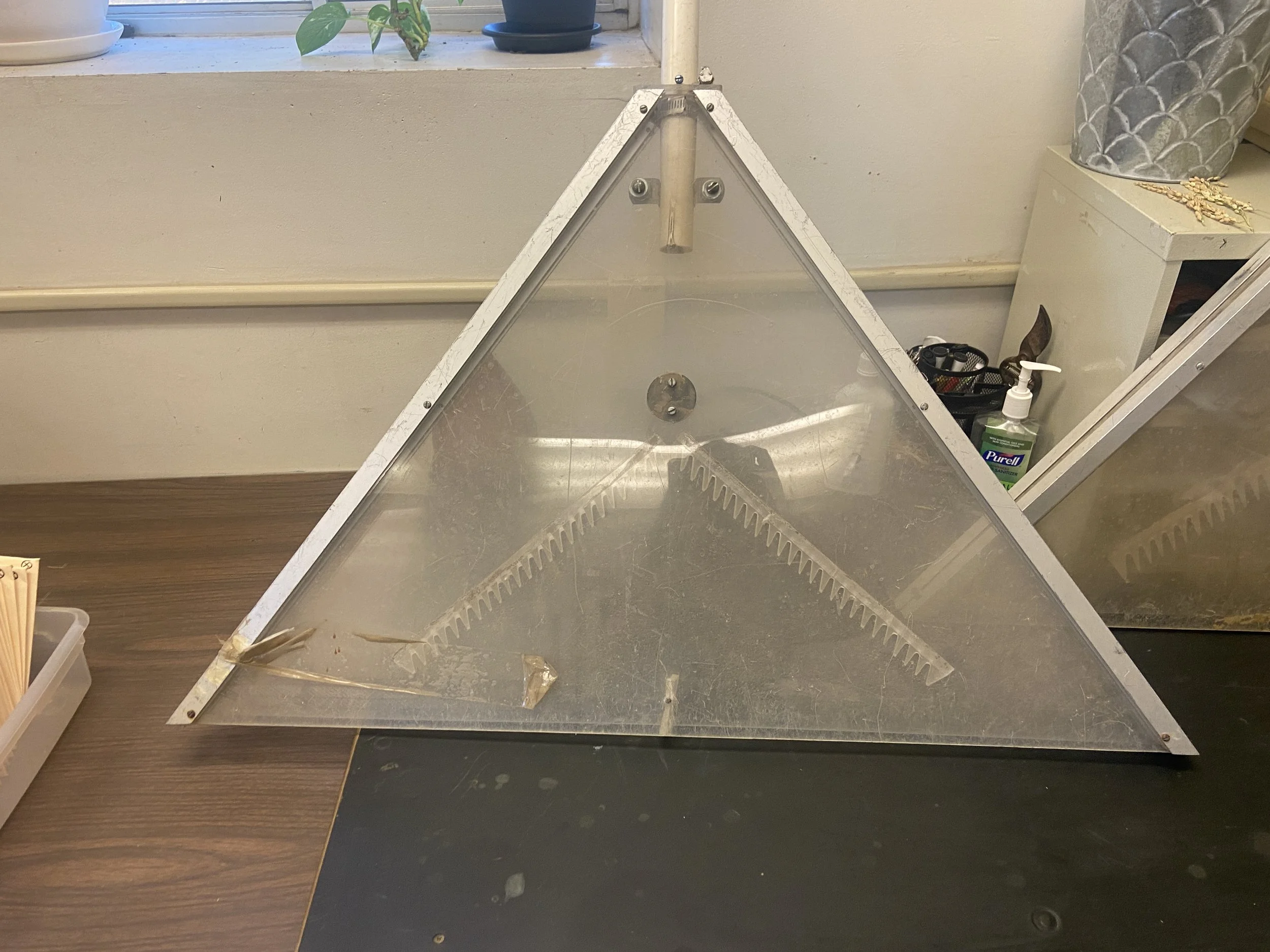

The client wanted more seed planters built, but wanted them to be lighter than the original. The original was made from PVC pipe, acrylic sheet, and aluminum extrusion. By using thin wall aluminum tube, thinner and tougher plastic, and formed aluminum sheet metal structural elements I was able to reduce the weight by half. The alignment spikes were later replaced with fasteners to attach multiple planters to a larger frame to maintain precise spacing.

The new planter

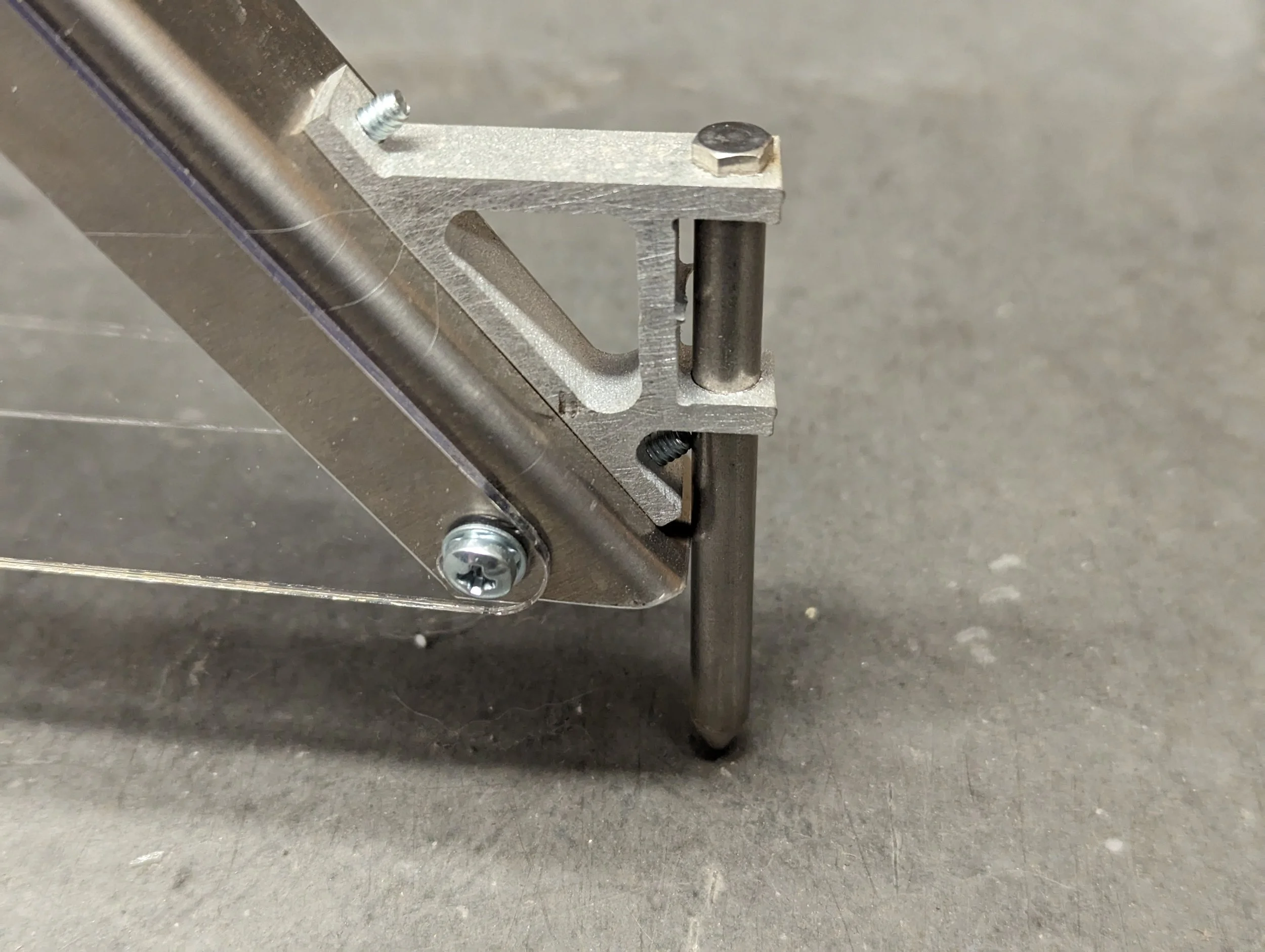

Inlet tube attachment plate

Spacing and alignment spike

The client's original planter.